Weldable Steel Fittings

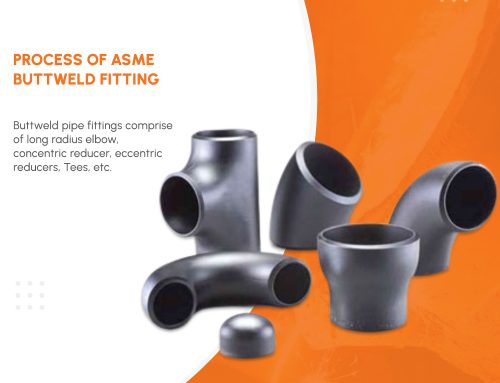

Welded steel pipe fittings are also known as buttweld fitting. It is built with an integrated component that includes carbon and stainless steel. They are used for nominal pipe size with a fixed schedule. In comparison to threaded fitting and socket welding, welded steel fittings have more benefits.

The quality of fittings should be excellent as the joints and piping systems are important. These are welded in the piping system, and removal is difficult; the accuracy seems to be more crucial. So if you are interested in buying the best quality, here are a few tips in order to get the best steel fittings.

How to identify the best quality fittings?

The connection joints of steel pipe fittings are quite essential, and the quality remains excellent. For weldable steel fittings quality is crucial as they are welded in pipe systems and difficult to install as well as dismantle. Weldable steel fittings

Check the specification

It is essential to monitor the dimension of fittings, diameters, and the ends of welding fittings. Because they should always match the ends of pipes. The diameters should be the same, and it will not bind it tight otherwise, it can cause leaks. There is high dimension tolerance in welded steel that is needed in conjunction.

Consistency in fittings

It is important to have a surface inspection when we speak about consistency in fittings and about size inspection. The surface quality when visually gets tested to make sure that fittings are not solid and hard. You can find the data easily seamless pipe manufacturers in gujarat, like manufacturing time, whether the stock is old or fresh. You can also get to know about the consistency of raw material, be it smooth or not.

Consider the MTC information

You need to consider MTC information for quality control. Get your quality data and information on fitting from the MTC as well as the test agreement. Now, you can determine if you want to accept the fittings for your project or not.

No cracks or chips

When you are going to verify the quality of these types of fittings, you need to make sure that there should be no cracks or chips found on the pipe ends. If there is rust or corrosion on the surface, certainly it’s time to replace them.

These are the best aspects that you need to look for when buying welded steel fittings. They are very critical to the piping system, and in a project where the attachment joints of piping systems are there, the standard should be optimal. The consistency is quite crucial as it is welded in the piping network, and it is very hard to mount or remove them.

Final Thoughts:

Choosing the weldable steel pipe fitting should be thoroughly reviewed and verified. Because it offers you improvements in functionality. Make sure all the fittings are tested, and they are all made according to requirement and condition as suitable. These will help you easily differentiate between the welded pipe fittings for your device and other ventures.

Read more: Stainless Steel Buttweld Fittings